I decided to post the whole guide on there so people can always view it, please notify me of any corrections/aditions/changes to be made.

Sam-Q's 20V RWD Cooling System Guide

With many different stories on how to convert a 20V engine into rear wheel drive form it seems that many people are under the false impression that water cross-over pipes are needed or even worse firewall modifications are necessary to make it work. Another article shows a way to avoid the cross-over pipes but requires a hole drilled into the head. This article is to show how to make a custom RWD cooling system that looks factory, works as well as factory, doesn't promote any air locks, doesn't have any extra external main pipes on the side of the engine, uses a completely standard engine (no drilled holes into the head), can keep the heater working and most of all no modifications to the body of the car such as the firewall.

When I did this conversion I tried as much as possible to make everything looking as original as possible. While this is very hard to do with any engine conversion it is however possible if done right.

Water Pump modifications:

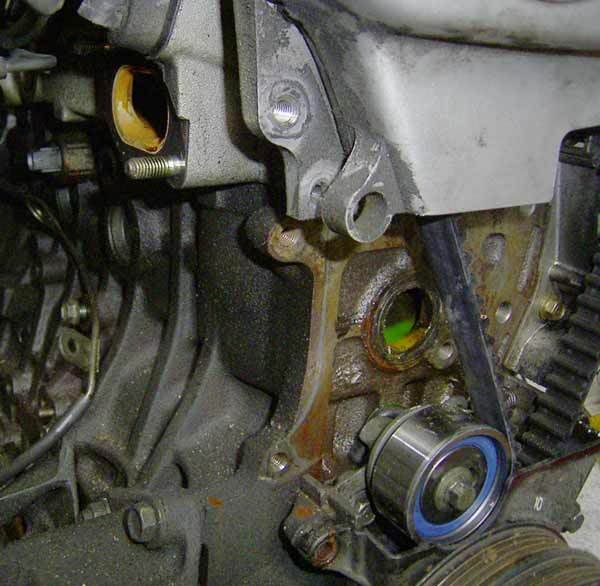

Remove the old water pump assembly and the top cast aluminum fitting, you will need to take the front timing belt belt cover off to do so. You should end up with this:

For the cooling system to work the rear half of 4Ac single cam pump is needed. I found a spare pump sitting in my back yard in the weather, it had been there for many years, needless to say time hasn't treated it well. I cleaned it up later with some acid based mag wheel cleaner which worked wonders. Heres it alongside the 20V one, notice how the 20V one has no provision for a thermostat (left):

While a 4Ac pump will fit straight on the 20V engine it in it's normal form is of no use. This is because even once the pulley is swapped from the 20V the spacing is wrong. Here is how it alings when this is done:

Notice how it sits too far forward to be aligned correctly. I have been told that using a pulley off a JDM RWD 4AGE 16V will correct this I prefer using what is already available. For this I used the front half of the 20V pump and the rear housing of the 4Ac pump. These however are not a direct fit. Looking at the two it's obvious that they are different:

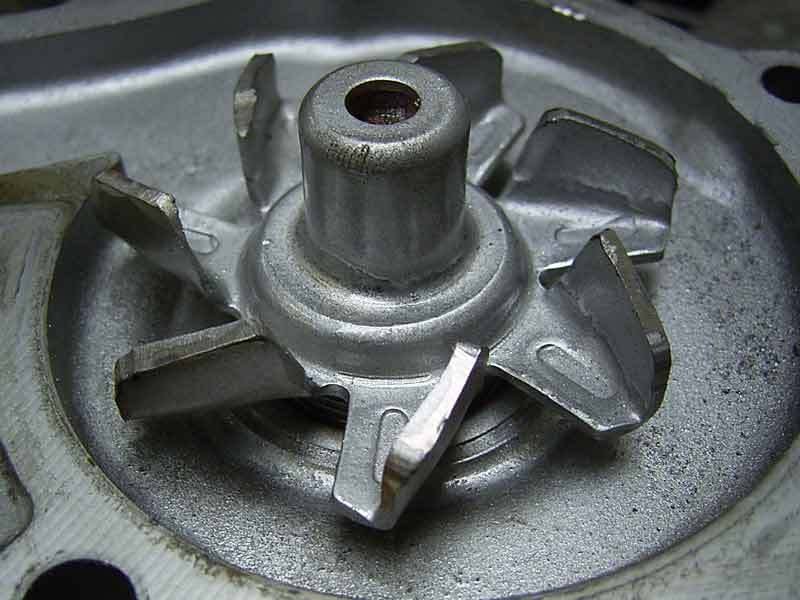

The 20V has one additional impeller blade and also has slightly higher blades than a 4Ac and therefore wont clear a 4Ac rear housing. The front half of the 20V can be made to fit though with a simple mod. For this I unbolted the pulley off the 20V front and carefully clamped it in a vice so as to face the blades upwards. From here is very carefully ground down the impeller blades about 1.5mm with a grinder. For this one slip can mean the end of the seal on the housing so I highly recommend having a person help by holding something like a piece of metal under the grinder wheel on the housing. This is so if the grinding wheel slips (trust me it's real easy) then it will hit the steel instead of the fragile aluminum housing. Whenever a piece is ground off do it evenly to all 7 blades in small intervals and then check it every time. For this just grab the housing and place it into the rear housing without the gasket. Once it turns freely throughout it's rotation then it is complete. If it is checked without the gasket in place then it will allow for extra fitting tolerances when the gasket is reinstalled. Here is how mine looked when the grinding was completed:

continued .....