taken from jase's build thread who posted on the previous page

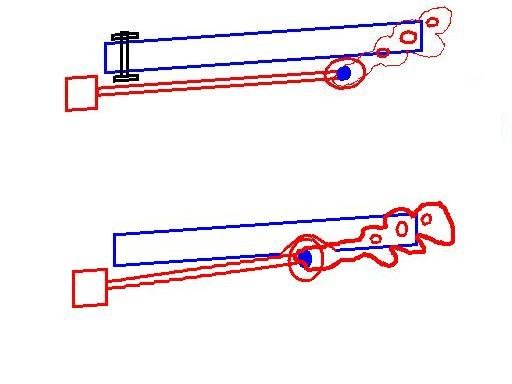

rack is forward 30mm

his own modified knuckle on top vs stock on bottom

There's a huge difference between bending and cutting+welding...

taken from jase's build thread who posted on the previous page

rack is forward 30mm

his own modified knuckle on top vs stock on bottom

stroked 2L ca18-ae86 in the build...eta xmas 2012?

chopping and rewelding is a damn sight safer and stronger than bending, clearly you have no idea how metal works, if somethings bent, its weakened, it will bend again

oh, and bending several times on a think solid peice of steel ultimately means SNAPPING, if you want your shit to snap, by all means bend it, or run the knuckles that have been breaking at track days in victoria

but there is only so far you can move your rack before other things get in the way like the bush and arm itself, so there is no way you can go past the straight of the arm and have any mechanical advantage left... so no reason to notch the arm

(even if you change the bush to a rose-joint and also offset mounting point on the crossmember you will still only get the tie-rod in line with the arm, so you still really need a 7-10mm stopper, even better if you use a stopper that is raised and stops the steering arm not the ball-joint)

(i've run a moved rack for a fair few years now) since back when i was drifting with a k series, you should move the rack on any setup you are getting the bail-joint near the lower control arm

I don't understand how you can say there is no advantage to notching the LCA..?

My LCA have a pretty massive amount missing, and my set up only just goes into bind when the rack end buttoms out in the LCA... And due to not having long enough rack ends I have to have my LCA shorter than I'd like which means my wheels rub the rail befor that any way..

But I do agree with most other things.

An very basic setup of Lock spacer and angle corrected arms results in heaps of lock..

And also as you said. There is little point to making them too short..

maybe mspaint can help explain better?

you barely have any mech advantage when hitting the lower control arm at full lock (if any), most people drive around this using weight transfer and caster to pull them out, but when you get it slightly wrong you can't pull it out of the slide when you want

if you have moved the rack as forward as possible, and you have notched the lca's and you run into binding issues, you are clearly doing something wrong

the wheel would be hitting the rack end before it binds........ or something else ridiculous

But just look at the awesome angle differnce

[/QUOTE]

Tom I'm not sure what your implying.??

Moving rack forward = less chance of bind.

Notching LCA = more chance of bind..

And As I've already said. My setup phiscally can't go into bind because the wheel runs out of room to turn.. If I had no wheel then yes it can and does bind. Mind you the angle this acheives is fairly stupid...

Annnndddd I'm pretty sure I did mention that I can over come this with a slightly differnt knuckle design and longer LCA when I can find an appropriate rack end to give me the length I need.

not sure where you got that first part from

second bit about not being able to go into bind is what i was trying to say.